AR-15 & 308 AR, Articles, Bolt Action Rifles, Technical Articles, Vintage Military Rifles

The Dirty Barrel Trend or: How I Learned To Stop Worrying and Love the Cleaning Rod

Is barrel cleaning good or bad for accuracy? “I don’t clean my barrel until group sizes start opening up.”

This line is becoming more and more prevalent in the precision rifle community. Theories fly about the internet on why shooters don’t clean their barrels. Common arguments include the importance of eliminating the need for fouling shots, disrupting the “bore uniformity” offered by copper fouling (spoiler alert: copper fouling buildup does not increase bore uniformity in hand lapped match grade barrels), fear of diminished barrel life due to over-cleaning, and a general feeling of pride that their rifle has functioned reliably for x number of rounds without maintenance.

While I have always strived to keep my firearms well maintained and serviceable, an opportunity recently presented itself to compare barrel maintenance procedures between two nearly identical precision rifle barrels.

Earlier this summer one of my coworkers (Mike Ross) and I both constructed rifle builds of similar design. My rifle was built off a Tikka T3 action, while Mike’s rifle was built off a Surgeon 591. Both were mounted in Kinetic Research Group Whiskey 3 chassis and featured 22” salt bath nitrided 6.5 Creedmoor Criterion pre-fit barrels.

For a period of three months we put a fair amount of time behind our respective rifle builds (by our standards at least). We utilized the same ammunition (PRIME Ammunition 130gr. OTM) at a similar rate of fire. These rifles were used for industry demo shoots, local PRS matches, and general target practice (often fired side by side).

The only significant difference between these two rifle builds was how the barrels were maintained. Mike’s rifle was properly broken in, with a regular barrel cleaning regiment after each use. Other than the barrel, my rifle was cleaned and lubricated, the action, bolt, and exterior components lightly oiled after each use. The interior of the barrel was not. Instead of taking care of the barrel as I normally do, I decided to put the new “dirty barrel trend” to the test, with no break-in period or regular barrel cleaning regiment. I figured with the salt bath nitride finish and its added corrosion resistance would render the internal finish virtually impenetrable to rust.

Drinking from the Kool-Aid of widespread keyboard commando lore, describing countless well-functioning but poorly maintained rifles, it would likely be thousands of rounds before I would notice group sizes opening up from excessive fouling, much less a failure in rifle function.

I was dead wrong.

It took three months and 700 rounds until I encountered my first failure to extract. A few weeks after my last range trip, I fired round #701 and placed the bullet exactly where it should have been zeroed. I then rotated the bolt knob and attempted to extract the round rearward. Nothing happened.

I then applied some additional rearward pressure. Nothing.

I yanked the bolt back on the third attempt with an extreme amount of force. The case popped out of the ejection port, landing a few feet away.

Investigating the cause of this extremely sticky bolt, I inspected the brass. Could it be a high-pressure round? The brass looked good. There was no cratering or flattening of the primer. There was also no ejector mark or any other signs of overpressure. During my inspection I did notice some slight variation in case body finish and texture, but didn’t think much of it at the time.

I decided to try firing another round. The bolt ran smoothly into battery, feeding the round easily. The second round fired. The steel target let out a satisfying ping. Through my scope I could see the second round impacted almost directly on top of the previous one.

The bolt required a Herculean effort to pull to the rear once again. Something was clearly wrong with this rifle. After inspecting the second round (Which also featured no pressure signs) I pulled the bolt out and inspected the extractor and ejector. Everything appeared to be well maintained and functioning properly with the bolt assembly.

As a former SAW gunner in the Marine Corps, I decided to try the classic field remedy for a non-functioning firearm. If all else fails, lubricate the hell out of it and try firing it again. Grabbing a bottle of CLP out of my range bag, I liberally lubricated the bolt, the action raceway, and the lug engagement surface.

I fired the rifle once more. The bolt was stuck once again.

Now convinced that the ammunition, receiver, and bolt assembly were not at fault, the barrel remained as the last variable in the equation. My forever unclean rifle barrel must have been the culprit.

The following day I brought my rifle back to the shop for a bore scope inspection. What I found during my first look down the bore simultaneously impressed and horrified me.

As I inserted the borescope into the base of the chamber it looked like the surface of Mars. Bright orange, craggy, and extremely uneven. As the saying goes, guns only have two enemies: rust and politicians. It was fairly clear that my barrel had been fighting a prolonged battle with the former.

But how could this be? I had never fired this rifle in the rain, although I had taken it out on a few humid afternoon range trips. The rifle was stored indoors in a climate controlled building between range trips, and had not fired any corrosive ammunition over the course of its life. While the rifle had been stored a few days in a Pelican case over the course of its use, it had spent the overwhelming majority of its service life stored muzzle up in a gun safe.

Even with the level of care taken to ensure the rifle wouldn’t rust, the humidity level inside the chamber must have been sufficient at one point to cause condensation, which eventually led to oxidation of the steel. A few lightly oiled patches run down the barrel after each range trip would likely have been sufficient to protect the internal surface of the chamber, but the “no cleaning” approach dictated that this was not to be the case.

I had also taken the added precaution of having the barrel salt bath nitrided to further protect it from rust and corrosion. Curious to confirm what effect salt bath nitriding has on the corrosion resistance of 416R stainless steel, I gave H&M Blacknitride a call to discuss this point further. Their Quality Manager confirmed my suspicions that the salt bath nitriding process does indeed serve to slightly improve the corrosion resistance of 416R stainless steel, as well as greatly improve corrosion resistance of 4150 chrome moly vanadium steel. I can only imagine how much additional rusting would have occurred had I left the steel of this barrel “in the white” and untreated.

Dismayed by the appearance of the chamber, I worked my way up the barrel to the shoulder, neck, throat, and rifling. I was surprised to discover that although the base of the chamber had rusted significantly, there was remarkably little fouling anywhere else.

This was further verified by running a pair of patches with Sweets 7.62 bore solvent (one a few minutes after the other), which left no blue or green residue on either patch. Another pair of patches of Rem-Oil (applied to neutralize the Sweets) left the patches a very light grey with minimal carbon fouling. One final dry patch was run through the bore upon completion of the initial cleaning session.

Copper and carbon fouling is normally minimal with Criterion salt bath nitrided barrels. This is partially due to the hand lapped finish of the bore, which is enhanced by the polished surface of the chamber and rifling. This serves to further reduce the friction coefficient offered by the salt bath nitride finish.

In order to alleviate future rusting and once again enable functionality of the rifle, I proceeded to polish the chamber aggressively. While some minor pitting remained, the rifle now cycles consistently and continues to produce tight groups. The rifle was taken to the range later that same afternoon, with the cold bore shot and subsequent five round group placing rounds directly on top of the rifle’s previous zero.

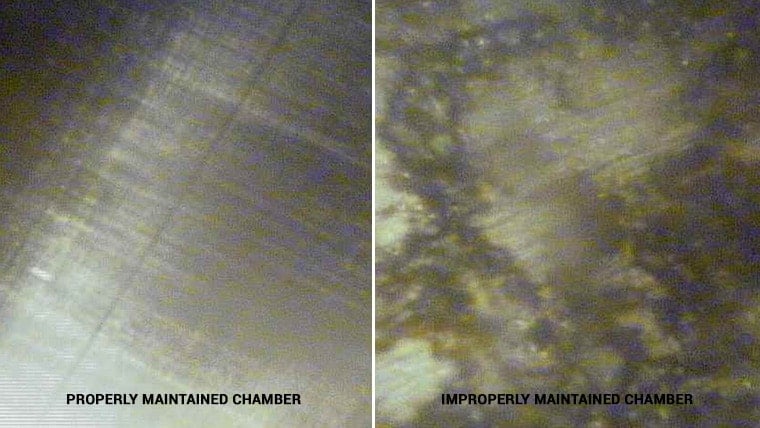

We had Mike bring his barrel in to verify that this rusting was indeed caused by improper barrel cleaning procedures. As was expected, the inside of his chamber and rifling was bright and clean, with no fouling or corrosion found throughout the full length of the barrel.

Shooters that follow the no cleaning approach to barrel maintenance will likely continue to claim that lightly cleaning the barrel after each use leads to premature wear and causes fliers before the barrel is “properly fouled” once again. After my firsthand experience attempting this approach I’m inclined to respectfully disagree. I’ve learned my lesson to take the words of “social media precision rifle gurus” with a much larger grain of salt, and to stick to barrel cleaning after each match or range session.

A dirty rifle will function well until it doesn’t. I feel much more comfortable knowing my equipment will operate as intended with each and every round fired, so from here on out I’ll be making a point to dedicate additional time toward regularly cleaning my firearms in order to cut down on corrosion and ensure proper function.

If you have any feedback or suggestions on this subject feel free to share it in the below comment section. We always welcome input, and would love to gain some additional knowledge from experienced shooters!

Edit: Some readers have expressed interest in simply cleaning and very lightly oiling the chamber after each use while leaving the rifling uncleaned. As there was no discernible rust or corrosion in the rifling this may be an interesting barrel cleaning experiment to test on a later date.

I have been in the service and “how dare you turn in a “dirty” weapon” was heard only once due to the diligent cleaning of the weapons systems. I had a chance to be at a talk with a local, medal winning, Camp Perry AR-15 shooter, who remarked when asked how often he cleaned his rifle, “only twice in a year of shooting”! As I am an old school competition shooter, I ‘ve never met any “great” shooters that didn’t clean between matches. Your article shows that even with the best barrel treatments, abuse leads to unplanned disappointments.

Great read, an over all accuracy comparison added to the article would have been very useful.

Very timely read for me. I just got a used Savage mod 10 fcp-sr. I checked the barrel for blockages and checked the operating parts. At the range I shot a few rounds to zero the new scope I mounted. As I moved out in range, I began to have bolt jams on the extraction. I also noticed that the bolt handle was harder to close on the rounds that were hard to extract. Since I was firing odd brass loaded for several .308’s, I figured that I may have some small base and regular reloads in the pile. Didn’t want to possibly hit the scope while pulling hard on the bolt handle. Got it home and checked different cases and found that size really didn’t affect it. I did a thorough cleaning on what turned out to be the filthiest barrel and chamber I think I have ever cleaned. Bottom line is that the rifle now chambers and extracts great. I’m a believer now. I even used my split dowel with green scotch brite patch on the chamber.

I will continue, as I have for 40 years, to clean my barrels after each match. I have NEVER ruined a barrel by over cleaning it. THAT IS A MYTH. I have seen many a barrel ruined or service life shortened by not cleaning. A match grade barrel will settle back in after the first round fired after cleaning. My first shots are normally with in a 1/2 inch high and left on 90 percent of my rifles. That has not cost me an X yet.

Very interesting article. I have had a similar experience with my Enfields (2). One is calibrated for heavy cast bullets and the other calibrated for 150 grain Hornady bullets. Both are scoped and I test accuracy with a lead sled to remove as many human errors as I can. I have been perplexed that sometimes the rifles would spread shots all over the paper, while at other times they were moa or better (2 moa for the cast bullet rifle). At the last trip to the range, I discovered that both rifles don’t even to come into their best until around 15-20 rounds were fired through them. The 150 gr rifle went from 3 moa to sub moa in my test, and the cast bullet rifle went from 9 moa to 2 moa, and both became consistant, so the temptation was to leave the chamber and the bores dirty, but thanks to your article, I am going to panic and go clean them immediately. Another situation (not mine) I saw an excellent condition 03A3 rifle neglected after exposure to a rainy day with heavy moisture present, where a shell stuck very firmly in the chamber. I believe that rifle may be damaged beyond hope if it is pitted. Great test…great article…thanks.