Articles, Industry Partner News, News

Criterion Shop Tour Part II: Seven Years Later

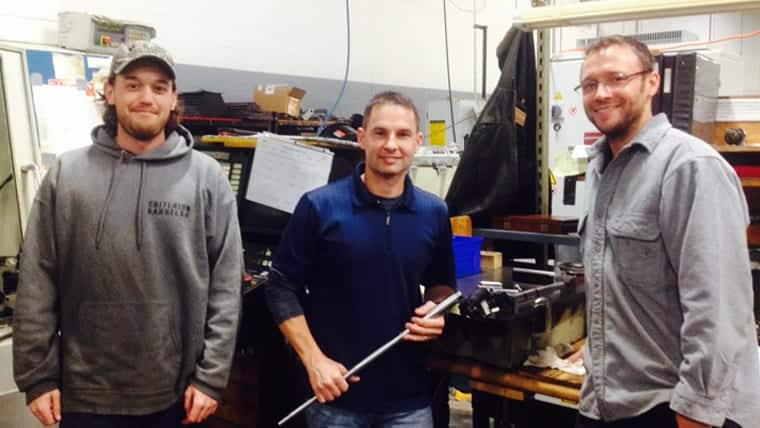

Seven years ago in September of 2007, I made the trek up to the Krieger/Criterion shop in Richfield, WI. A few days ago, I made the trek again, but this time my focus was exclusively on Criterion’s new shop in Germantown, WI. Criterion Barrels Inc., is now wholly owned by Steve Dahlke and his new manufacturing facility in Germantown is a top notch operation.

Imagine a place where innovation, creativity and American ingenuity really exist. A place where the people on the shop floor take ownership, and have been empowered to make changes and improvements on the fly. Imagine a place where every person in the shop is part of the family, and credit for superior work is given to those who earn it. This is Criterion Barrels Inc.

Although much has changed since my last visit seven years ago, the fundamentals have not. The company is chock full of talent at all levels and in all departments. Criterion has that can-do attitude, lean efficiency and turn on a dime mentality that once defined the greats in American business.

Criterion’s new shop is logically laid out in a manner that maximizes efficiency. Barrel steel is segregated by type, and is precut, coded and palletized. The subsequent operations include not in exact order drilling, buttoning, stress relief, turning, milling, and chambering. What I discovered during my second visit is that the barrel making process is very labor intensive because of all of the inspection procedures performed during each phase. If you like all things precise, this place is teeming with inspection gauges, bore scopes, huge granite plates, run out gauges and fixtures and a new device is in the works to more precisely measure the rate of twist. Rate of twist must either be perfectly consistent breach to muzzle, or slightly increase. A slight increase in the twist is thought to create better accuracy, but a twist that slows towards the muzzle is a detriment to accuracy. This is why the rate of twist is constantly monitored.

As a product of their market reputation and successful operation, Criterion is now making more barrels than at any point in the company’s storied history. They produce M14, M1 Garand, M1 Carbine, M4, AR10, AR15, Enfield, Savage and others. The barrels are respected for precision, consistency and for their fine machining qualities.

The question that is often asked of me is why do Criterion barrels shoot so well? What is it that makes them so highly regarded? I cannot discuss certain aspects of their operation, but I can say that they have figured out a system that works to make a superbly consistent barrel. While I believe there is room for improvement in everything, the Criterion barrel is hands-down the best barrel for the money invested. What’s more, it is evident, that the discipline of reinvesting proceeds back into the operation in order to set the foundation for a continuous quality improvement process is alive and well at Criterion.

Barrel performance is often a mystical thing. However there are a few things that make for a superb barrel. Stress relief and end to end consistency have great impacts on a barrel’s performance. A barrel that has smaller bore dimensions at the breach end, than it does at the muzzle end is not inherently as accurate as a barrel that is consistent throughout. Button rifling tends to cause this condition if the outside diameter of the muzzle end is machined smaller than the breach end, which is the case for M14 type barrels. The stress in the steel from buttoning, pushes outward, and when a barrel is profiled more narrowly at the muzzle end, the stress from the button is allowed to open up the bore diameter.

Criterion has resolved this condition and has discovered a way to create consistency end to end. This combined with their stress relief process makes their barrels superbly consistent, not only for the first five or so shots, but for long strings as well. Across the course competition requires firing long strings with a warm and often hot barrel. If there is enough stress in the barrel, the barrel and subsequently the point of impact will move when it warms up. This condition is usually present in all barrels, but I have found that Criterion has minimized this condition and barrels shoot consistently whether cold, warm or hot. This in and of itself it as major accomplishment.

I have had the great fortune of working with thousands of barrels during the installation, testing and fine tuning process of M14 and M1 rifles over the years. A large majority of those barrels were Criterion. My personal and professional experience with their barrels has been exceptional.

Jon Y. Wolfe is the Founder and President of M-14 Parts and Armory.

The original 2007 shop tour article can be found here.