Articles, Media Reviews, News, Reviews

Bringing History To Life: Criterion’s Vintage Barreling Machinery

(originally published in the Summer 2015 issue of the GCA Journal)

While Criterion Barrels Inc. utilizes some of the most cutting edge CNC barrel manufacturing technology to ensure our products maintain strict adherence to design specifications, sometimes the tried and true methods offer an ideal solution for the barrel production process.

The Criterion Classics line of products includes direct replacement barrels for rifles originally issued throughout the early 20th Century. From the Krag- Jorgensen to the M1 Garand, Criterion barrels continue to breathe life into well-worn rifles, some of which may be over one hundred years old. It is remarkable to discover that amongst the rows of modern manufacturing equipment lining Criterion’s 72,000 square foot production facility, a few machines can still trace their roots to World War II arsenal production.

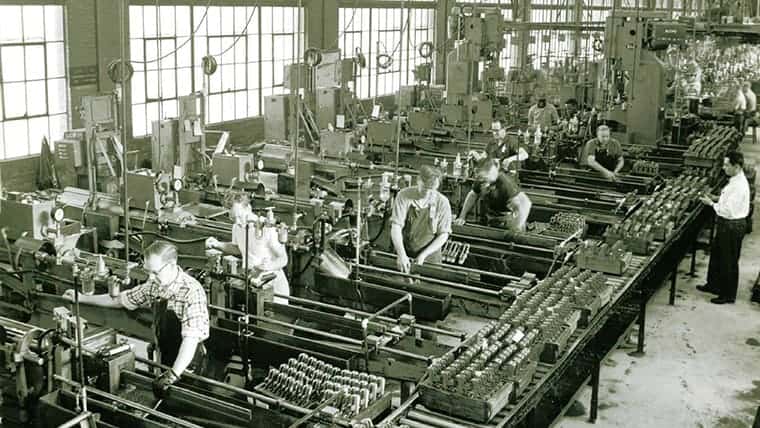

It is a little known fact that each Criterion barrel is partially formed by machines that once labored tirelessly to arm our soldiers, sailors, and Marines with the finest battle rifles of the period. Originally used to produce barrels for the 1903, 1903A3, and M1 Garand, Criterion’s vintage Pratt & Whitney gun drills continue to turn out barrels for those same rifles to this very day.

Barrel drilling can be a lengthy process, so Criterion owns and operates a number of these drills. Each drill features multiple spindles, providing CBI the capability to drill large quantities of barrels simultaneously.

The first two drills were prospected from an arsenal auction, while others were purchased from other manufacturers who had acquired them from government sales. Criterion’s latest gun drill was completely rebuilt in-house by our employees.

The gun drill was disassembled down to the bed upon arrival, and was then ground and stripped prior to the reassembly. The spindles, bearing, and chip boxes were then fabricated in-house.

These gun drills are not the only pieces of machinery to claim a level of historical significance. Criterion also operates a reamer that was built atop the remnants of a WWII era Pratt & Whitney rifler that arrived with a leader bar that had previously been set for a 1-15 twist. Criterion President Steve Dahlke believes the rifler was originally tooled to produce barrels for the classic Browning M2 “Ma Deuce” .50 caliber machine gun.

Rounding out the list of historic equipment are a number of Pratt & Whitney chambering machines acquired from the Rock Island Arsenal. These mechanisms were originally tooled for .50, .30, and .22 caliber production.

Every one of these machines continues to fulfill its role in producing vintage replacement barrels, a specialty process that Criterion has mastered over the course of its production history. The Criterion Classics product line offers a perfect blend of modern and historic barrel production techniques, allowing Criterion to manufacture barrels to original specifications while maintaining the precise tolerances inherent in modern production processes.

Criterion vintage reproduction barrels are available for purchase from a number of dealers and distributors. The Civilian Marksmanship Program, Rock Ridge Machine Works, James River Armory, and Fulton Armory all produce vintage reproduction rifle designs featuring Criterion barrels.